Stairs in industrial facilities, as well as single steps and thresholds are often key high traffic areas in industrial facilities and represent an area of risk when it comes to accidents on-site.

According to the UK Slip Resistance Group, an independent authority which aims to promote a greater understanding of the causes and prevention of slips, 20% of occupational ‘Slip Trip and Fall’ (STF) accidents occur on stairs at the rate of one every 25 minutes!

Approved Document K and UKSRG set out guidelines for stair construction that aim to reduce the risk of slips and trips on stairs, focused on their dimensions, consistency, nosing accents and colour, as well as handrails, lighting and ongoing cleaning and maintenance.

While the guidelines may not specifically address coatings or floor coverings, the choice of flooring material remains pivotal in upholding safety standards and mitigating risks associated with slips and trips.

Stairs in industrial facilities, if not properly maintained, can accumulate wear and tear over time, leading to uneven surfaces and diminished traction. This, coupled with the often hectic pace of industrial environments, significantly increases the likelihood of accidents. Resin flooring offers inherent properties that contribute significantly to adherence to the guidelines set out by Approved Document K and UKSRG.

Resin flooring’s seamless application helps to eliminate uneven surfaces and trip hazards. Additionally, its customisable nature allows for the incorporation of anti-slip aggregates and textures, enhancing traction and minimising the risk of accidents, especially on stairs and thresholds. The chemical resistance and durability properties of resin flooring also help to reduce the need for frequent repairs, contributing to the overall safety of industrial facilities.

In this context, while resin flooring may not be mandated by regulatory guidelines for stairs in industrial facilities, its inherent properties align closely with their objectives, making it a prudent choice for improving safety and compliance in high-traffic industrial environments.

The devil is in the detail

When tackling the stairs, resin flooring applicators will typically employ a number of specialist installation techniques in order to create a safe finished installation.

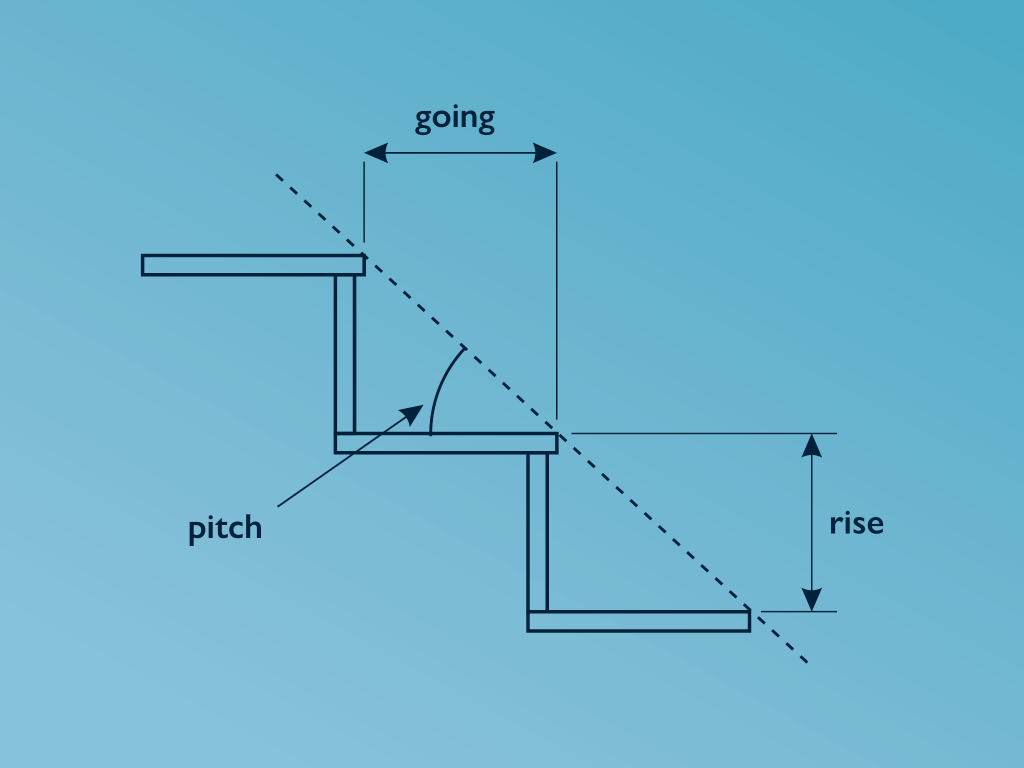

Firstly, the ‘going’ of each step (also known as the stair tread), will often be coated using a slip resistant resin flooring system that comprises specialist aggregates that increase the texture of the finish, providing traction underfoot.

Vebro Polymers’ high-build coating system, vebrores EP HBC has a slip-resistant sister in vebrores EP HBC SR. Because the core products that comprise each of the two systems are the same, the colours and patina are the same, meaning the ‘risers’ of each step, as well as surrounding areas that call for a smoother finish, can match seamlessly without the need for enhanced texture across the board.

vebrores EP Quartz SR – and its methyl-methacrylate (MMA) counterpart, vebrospeed Quartz SR – deliver a slip resistant, positively textured finish with a decorative aesthetic.

The nosing of steps can be tackled in one of two primary ways.

Firstly, applicators can create a saw-cut in the resin and substrate that allows for the installation of a proprietary stair nosing.

Alternatively, the edge of each step can be taped off and a contrasting colour of epoxy or PU coating materials can be applied to highlight the nosing.

With each, the guidelines set out in Approved Document K and UKSRG stipulate a contrasting Light Resistance Value (LRV) of greater than 30 points. For example, if the material used on the step has an LRV of +45, that of the nosing colour must be no greater than +15.

In the UK, Vebro Polymers’ range of epoxy high-build and self-levelling coating materials are available in a range of 18 stocked colours – 9 Glorious Greys and 9 Brilliant Brights that include a range of shades across the LRV spectrum and are kept in stock at all times to ensure a quick turnaround on these staple polymer flooring products.

Looking for more on industrial flooring?

Vebro Polymers offers a number of seamless industrial resin flooring systems that have been designed to meet a whole host of service challenges faced in industrial and manufacturing facilities.

The includes a number of different epoxy and polyurethane resin flooring systems from the vebrores range, as well as a durable MMA quartz system from the vebrospeed range and a number of heavy-duty polyurethane concrete systems from the vebrocrete range for more demanding environments.

Any questions?

If you’re a Facilities Manager, building owner or responsible for the upkeep and maintenance of an industrial unit and you have your own questions about resin flooring, the Vebro team will be happy to help!

Contact the Vebro team in Manchester, UK by dropping an email to hello@vebropolymers.com.