vebrospeed Flake

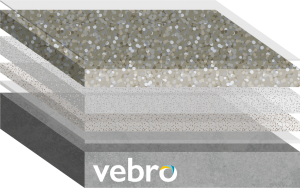

vebrospeed Flake is a highly decorative and durable UV-stable flooring system based on ultra fast-curing MMA (methyl methacrylate) resin technology.

Home > vebrospeed

vebrospeed is range of fast-cure flooring systems designed to accelerate the speed of cure of resin flooring even further on new-build projects with a narrow installation window or in refurbishment or upgrade scenarios where a fast return to service is a must-have.

The main benefit of vebrospeed systems is their accelerated speed of cure, which makes them an excellent choice for new-build and upgrade projects where timesaving and programme efficiency is critical.

In most scenarios, vebrospeed systems are ready to walk on in 60 minutes, which is highly advantageous where follow-on trades require early access, or a facility requires a prompt return to service.

Aside from this, vebrospeed continues to offer the same performance benefits of resin flooring include excellent durability and wear resistance.

vebrospeed is available in both a colourful quartz and decorative flake blend. Typically, the quartz system is used in more demanding industrial processing areas and catering kitchens or alternatively wet areas of commercial premises such as WC or changing room facilities.

The flake system is highly decorative and can be used in frequently trafficked retail, leisure and office facilities.

All systems come in a range of colourful aggregate blends or can be tailormade to custom or corporate colours on request.

vebrospeed Flake is a highly decorative and durable UV-stable flooring system based on ultra fast-curing MMA (methyl methacrylate) resin technology.

vebrospeed Quartz is a highly durable and slip resistant, UV-stable quartz flooring system based on fast-cure MMA (methyl methacrylate) technology.

vebrospeed Quartz SR is a highly durable and slip resistant, UV-stable quartz scatter flooring system based on fast-cure MMA (methyl methacrylate) technology.

| Title | Solutions | Applications | Download |

|---|---|---|---|

| vebrospeed Flake | vebrospeed | Commercial Venues, Retail & Shopping Centres | |

| vebrospeed Quartz | vebrospeed | Commercial Venues, Industrial & Manufacturing, Retail & Shopping Centres | |

| vebrospeed Quartz SR | vebrospeed | Commercial Venues, Food & Beverage Processing, Industrial & Manufacturing |

Resin flooring can sometimes be more expensive in the short term than using other materials, this can be as a result of a potential increased cost of materials as well as the outlay for specialist trained resin contractors to install the product, but its durability alone makes it an extremely cost-effective option, as you won’t need to replace it for many years.

And, when you take into account other savings that you can generate as a result of selecting resin flooring, such as reduced maintenance, cleaning and energy costs, it makes sense that an investment now will continue to pay dividends in the long term too!

MMA is considered a specialist product; and due to the material’s reduced working time, applicators need to be trained on the correct installation techniques by the manufacturer to ensure effective installation. Vebro Polymers can recommend a number of trained applicator partners who are able to quote your MMA resin flooring project.

The curing process of traditional epoxy and polyurethane systems with longer cure times could be affected by precipitation or temperature cycling, but owing to its incredibly quick speed of cure, MMA flooring systems can be installed outside with little concern for changing weather conditions.

MMA systems are also UV-stable, so once they have been installed in outdoor locations, their colour will remain unaffected by exposure to sunlight.

Slips and trips are one of the most common accidents that occur in the workplace, and one of the reasons for this can be unsuitable floor coverings. With a staff body to protect, it is important to consider this when choosing a floor finish, as well as the service criteria that a floor will be subject to.

For example, areas subject to either wet processes, frequent spillages or those that employ rigorous cleaning regimes such as steam cleaning or hot water wash downs should take particular care to ensure an anti-slip finish when replacing floor coverings or coatings.

Liquid-applied resin floor systems are great to custom build any safety features that you require from your floor within your workspace, surface profiles can be tailored to include quartz, aluminium oxide, glass spheres or silicon carbide in order to enhance the slip resistance profile of the floor finish.

Resins are seamless in nature and don’t include joints or grout lines, which are susceptible to harbouring dirt, grease, bacteria and stains in general. Dust and dirt can simply be swept, mopped or hoovered away and the floor cleaned according to manufacturer’s guidelines based on the surface profile of the floor.

Resin flooring is also extremely strong and durable, meaning that it has an extended service life compared to other floor coverings. Installed properly, and with the correct maintenance, it can last for years without cracking or peeling, meaning that you won’t have to replace the floor or carry out repairs as frequently than you would if using other materials.

During the cure process of MMA floor coating materials, each layer effectively welds itself to the previous coat. This creates a monolithic coating that is incredibly durable and will not delaminate.

The seamless application of MMA flooring results in a surface that is free of joints, grooves and other areas where bacteria naturally builds up.

Its impressive durability also minimises the risk of damage from dropped tools, objects or equipment, so the integrity and inherent seamless hygienic nature of the floor finish is maintained.

Not only does MMA flooring cure in as little as one hour, meaning operations in facilities where the floor is being refurbished can return to normal quickly, MMA floor coating systems can also be installed over a variety of substrates, including steel, concrete and tiles.

Cured MMA flooring does not smell, and while the smell exhibited by the liquid components of MMA flooring can be unpleasant, it is not considered dangerous.

Installation teams can minimise the smell during installation, as well as any odours that may linger, by ensuring adequate ventilation and using appropriate extraction equipment.

Because MMA flooring materials can cure in temperatures as low as -30°C, this ventilation is very unlikely to interfere with the curing process.

MMA resin flooring is best known for its rapid cure and versatility. MMA-based acrylics can be installed fast and fully cure in less than two hours in temperatures as low as -30°C.

In addition, MMA resin flooring exhibits very high scratch resistance, can withstand service temperatures up to 70°C, has a low-glare satin matt finish and is often available in a decorative range of colours and finishes including decorative PVA flake and quartz blends.

MMA resin flooring also has an excellent chemical resistance profile and can withstand a wide range of acids and caustics, especially the organic acids used in the food processing industry.

The low-temperature cure capability allows them to be used during cold weather and in freezers and coolers. They are highly resistant to UV light, staining and marring, and they do not chalk or yellow.

The chemical resistance of flooring materials largely depends on a number of specific factors, including the type of chemical, its concentration, and the temperature and degree of surface contact time.

Polyurethane Concrete

Generally speaking, polyurethane concrete systems such as vebrocrete offer a good degree of chemical resistance to a wide range or acids, alkalis, and solvents. For low to medium concentrations of organic acids such as hydrochloric, acetic, lactic and formic, polyurethane systems demonstrate excellent chemical resistance.

However, some stronger concentrations of these types of acid can cause some surface staining, usually without loss of physical strength properties even at elevated temperatures over prolonged surface contact.

Additionally, polyurethane concrete systems offer excellent chemical resistance to solvents and alkalis at low, medium and high strength concentrations at prolonged periods of contact and temperatures with minimal surface staining and loss of physical strength properties.

Methyl-methacrylate

For chemical resistance to high strength organic acids, even with prolonged exposure, methyl-methacrylate (MMA) chemistries such a vebrospeed offer superior resistance against surface staining without loss of physical strength properties. Additionally, MMA systems offer good chemical resistance to a variety of alkalis at various strength and concentrations. However MMA systems are generally not suited to solvents and should be avoided in facilities where solvents will be present.

Epoxy

Epoxy systems, such as various systems in the vebrores range, are generally suited to weak to medium strength acids including organic and inorganic acids like boric and phosphoric, but are not suited to high concentration organic and inorganic acids. Epoxy systems generally offer good chemical resistance to a variety of alkalis at various concentrations, but are more susceptible to attack from medium strength acids at elevated temperatures. Epoxy systems have limited chemical resistance to solvents dependant upon solvent type, temperature and duration of exposure.

For the latest news, info and updates from Vebro Polymers…

The Social Hub has chosen Vebro Polymers materials to transform a number of accommodation, co-working and relaxation spaces in its Glasgow venue. The Social Hub, located in the

Read MoreAre you passionate about sales and ready to take your career to the next level? Look no further! We are seeking a dedicated and dynamic Sales Executive to

Read MoreWe are delighted to announce that Vebro Polymers is now proudly part of the Made in Britain manufacturing community. The not-for-profit organisation, dedicated to supporting British manufacturers

Read MoreVebro Polymers has manufacturing and office headquarters in Manchester, UK and Kuala Lumpur, Malaysia, as well as a number of distribution partners. Please choose your nearest Vebro HQ or distribution location to see local content.