vebrocrete SR

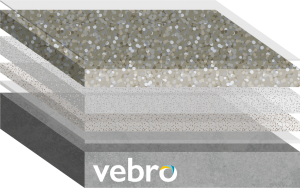

vebrocrete SR is a HACCP International certified easily-applied, polyurethane concrete, with a broadcast aggregate layer and pigmented top coat, offering excellent slip resistance.

Home > Industrial & Manufacturing

Floors found in industrial and manufacturing facilities are exposed to a wide range of different service criteria including heavy equipment and plant machinery, aviation oil spillages, hazardous chemicals, frequent forklift-truck traffic, electrostatic discharge – we could go on and on!

In addition to this, ensuring the safety of the workforce underfoot is a key concern in these facilities; this can range from providing slip-resistant finishes designed to reduce slip and trip related accidents, particularly in areas subject to wet processes, through to effectively zoning workflows and process areas through colour blocking and demarcation.

Selecting a flooring system that can meet the individual service needs of the manufacturer, protect employees underfoot and offer demarcation and zoning options is important in these facilities.

Vebro Polymers offers a number of seamless industrial resin flooring systems that have been designed to meet a whole host of service challenges faced in industrial and manufacturing facilities.

The includes a number of different epoxy and polyurethane resin flooring systems from the vebrores range, as well as a durable MMA quartz system from the vebrospeed range and a number of heavy-duty polyurethane concrete systems from the vebrocrete range for more demanding environments.

vebrocrete SR is a HACCP International certified easily-applied, polyurethane concrete, with a broadcast aggregate layer and pigmented top coat, offering excellent slip resistance.

vebrocrete RT is a HACCP International certified heavy duty, rake applied, polyurethane concrete mortar, with enhanced flow, offering excellent chemical, thermal shock and wear resistance.

vebrores EP SC is a two-coat water-based, easily-applied seal coating available in a coloured matt or gloss finish.

vebrores EP Quartz Classic is a durable, hand–trowelled epoxy quartz flooring system available in a colourful and decorative range of quartz aggregate.

vebrores PU HBC is a pigmented, solvent–free, flexible, high build polyurethane floor system designed to protect concrete substrates.

vebrores PU SL HD is a heavy duty, solvent–free, flexible, self–smoothing polyurethane flooring system offering outstanding strength and performance.

vebrores EP HBC is a pigmented, solvent-free, easily-applied high build epoxy floor coating designed to protect concrete substrates.

vebrospeed Quartz is a highly durable and slip resistant, UV-stable quartz flooring system based on fast-cure MMA (methyl methacrylate) technology.

vebrospeed Quartz SR is a highly durable and slip resistant, UV-stable quartz scatter flooring system based on fast-cure MMA (methyl methacrylate) technology.

vebrores EP HBC HCR is a pigmented, high-chemical resistance, easily-applied, high build epoxy floor coating system designed to protect against aggressive chemicals and solvents including Skydrol aviation hydraulic fluid.

vebrores EP SL is a solvent-free, easily-applied, self-smoothing epoxy flooring system, designed to protect concrete substrates, offering outstanding strength and performance.

| Title | Solutions | Applications | Download |

|---|---|---|---|

| vebrocrete ESD MF | vebrocrete | Food & Beverage Processing, Industrial & Manufacturing | |

| vebrocrete ESD Terrazzo | vebrocrete | Industrial & Manufacturing, Food & Beverage Processing | |

| vebrocrete MF | vebrocrete | Food & Beverage Processing, Industrial & Manufacturing | |

| vebrocrete RT | vebrocrete | Food & Beverage Processing, Industrial & Manufacturing | |

| vebrocrete RT | vebrocrete | Food & Beverage Processing, Industrial & Manufacturing | |

| vebrocrete SL | vebrocrete | Industrial & Manufacturing, Food & Beverage Processing | |

| vebrocrete SR | vebrocrete | Food & Beverage Processing, Industrial & Manufacturing | |

| vebrocrete SR | vebrocrete | Food & Beverage Processing, Industrial & Manufacturing | |

| vebrores Compact Industrial | vebrores | Industrial & Manufacturing | |

| vebrores EP HBC | vebrores | Industrial & Manufacturing | |

| vebrores EP HBC Composite | vebrores | Industrial & Manufacturing | |

| vebrores EP HBC HCR | vebrores | Industrial & Manufacturing | |

| vebrores EP HBC MT | vebrores | Industrial & Manufacturing | |

| vebrores EP HBC SR | vebrores | Industrial & Manufacturing | |

| vebrores EP Mortar | vebrores | Commercial Venues, Industrial & Manufacturing, Multi-Storey Car Parks | |

| vebrores EP Quartz Classic | vebrores | Industrial & Manufacturing, Retail & Shopping Centres | |

| vebrores EP Quartz SR | vebrores | Commercial Venues, Industrial & Manufacturing, Retail & Shopping Centres | |

| vebrores EP SC | vebrores | Industrial & Manufacturing | |

| vebrores EP SL | vebrores | Industrial & Manufacturing | |

| vebrores EP SL HCR | vebrores | Industrial & Manufacturing | |

| vebrores EP SL SR | vebrores | Industrial & Manufacturing | |

| vebrores EP Topcoat SR | vebrores | Industrial & Manufacturing | |

| vebrores PU HBC | vebrores | Industrial & Manufacturing | |

| vebrores PU SL HD | vebrores | Industrial & Manufacturing | |

| vebroscreed Industrial | vebroscreed | Commercial Venues, Industrial & Manufacturing, Institutional Buildings, Retail & Shopping Centres | |

| vebroscreed Top | vebroscreed | Commercial Venues, Industrial & Manufacturing, Institutional Buildings, Retail & Shopping Centres | |

| vebrospeed Quartz | vebrospeed | Commercial Venues, Industrial & Manufacturing, Retail & Shopping Centres | |

| vebrospeed Quartz SR | vebrospeed | Food & Beverage Processing, Industrial & Manufacturing, Commercial Venues | |

| vebrostatic ESD Quartz (Conductive) | vebrostatic | Industrial & Manufacturing | |

| vebrostatic ESD SL (Conductive) | vebrostatic | Industrial & Manufacturing | |

| vebrostatic ESD SL (Dissipative) | vebrostatic | Industrial & Manufacturing | |

| vebrostatic PU ESD SL (Conductive) | vebrostatic | Industrial & Manufacturing | |

| vebrostatic PU ESD SL (Dissipative) | vebrostatic | Industrial & Manufacturing |

Resin flooring can sometimes be more expensive in the short term than using other materials, this can be as a result of a potential increased cost of materials as well as the outlay for specialist trained resin contractors to install the product, but its durability alone makes it an extremely cost-effective option, as you won’t need to replace it for many years.

And, when you take into account other savings that you can generate as a result of selecting resin flooring, such as reduced maintenance, cleaning and energy costs, it makes sense that an investment now will continue to pay dividends in the long term too!

In a nutshell, yes. Although typically installed in institutional and commercial venues, comfort resin flooring offers the same safety benefits enjoyed by high-build and self-smoothing polyurethane flooring systems such as excellent durability, chemical, UV and slip-resistance.

An extremely flat finish can be critical in the finished goods or raw materials warehousing area of an industrial facility, where racking aisles may be narrow and stacked high. A slight deviation in the floor level could spell disaster for forklift truck operators attempted to retrieve goods.

Epoxy, polyurethane and MMA resin floor systems have a self-smoothing property and, provided their installed by an experienced applicator, are capable of achieving SR1 flatness, making them ideally suited to warehouse spaces.

Their seamless application also means that there are no grout lines or breaks in the floor surface in the driveways of warehouse aisles.

Understanding the need for and importance of ESD compliant footwear is also critical in the performance of the ESD flooring chosen. Personnel grounding requires effective ESD footwear that is appropriate to the application, properly worn and in good repair.

Without the use of special ESD footwear – heel straps, toe straps, sole straps or ESD shoes – some static control floors do not prevent static from accumulating as people walk.

The type of footwear used in the space also affects charge generation. Shoes with PVC soles, for instance, generate more static than shoes with leather soles. Because of its triboelectric propensities, leather is naturally low charge generating; leather also absorbs moisture, which acts as a conductor to reduce static charges. However, the anti-static tendency of leather is not reliable; in lower humidity ranges, leather shoes are not always anti-static.

Demarcation and colour blocking across the floor space can be used in industrial workspaces to notify employees and visitors of workflows, warn of any potential risks, hazards or dangers as well as highlight safe walkways and / or areas that should remain clear and accessible.

Resins are also available in virtually an unlimited palette of RAL colours to complement any floor demarcation processes that you may have in place.

Slips and trips are one of the most common accidents that occur in the workplace, and one of the reasons for this can be unsuitable floor coverings. With a staff body to protect, it is important to consider this when choosing a floor finish, as well as the service criteria that a floor will be subject to.

For example, areas subject to either wet processes, frequent spillages or those that employ rigorous cleaning regimes such as steam cleaning or hot water wash downs should take particular care to ensure an anti-slip finish when replacing floor coverings or coatings.

Liquid-applied resin floor systems are great to custom build any safety features that you require from your floor within your workspace, surface profiles can be tailored to include quartz, aluminium oxide, glass spheres or silicon carbide in order to enhance the slip resistance profile of the floor finish.

Antistatic floor coatings create a preferred pathway for the flow of electricity to follow, keeping the electrical charge under control as the charge is drained to a suitable earthing point.

The floor coating contains conductive elements that transmit the electrical flow through the full thickness of the coating. It is then transmitted into through a copper earthing tape, onto which the resin floor finish is laid.

Think of the grounding point as a plug hole and the electrical charge as bath water. The water (electrical charge) drains over the resin anti-static floor and is removed via the plug hole (grounding point).

The rate at which an electrostatic charge is dispersed within and through the floor finish is controlled by the floor coating material’s electrical resistance, measured in ohms (Ω), and usually expressed in thousands (kilo-ohms or KΩ) or millions (mega-ohms or MΩ).

Conductive

Static conductive resin flooring is defined as having and electrical resistance of less than 1.0 × 10⁶ Ω (1 million ohms). These have a low electrical resistance, so electrons flow easily across the surface or through the bulk of these materials. Charges go to ground or to another conductive object that the material contacts or comes close to. Conductive materials have a surface resistivity less than 1 × 10⁵ Ω/sq, or a volume resistivity less than 1 × 10⁴ Ω-cm.

Dissipative

Static dissipative resin flooring is generally defined as having an electrical resistance of between 1.0 × 10⁶ Ω and 1.0 × 10⁹ Ω. For these materials, the charges flow through the material slowly and in a somewhat more controlled manner than with conductive materials. Dissipative materials have a surface resistivity equal to or greater than 1 × 10⁵ Ω/sq but less than 1 × 10¹⁰ Ω/sq or a volume resistivity equal to or greater than 1 × 10⁴ Ω-cm but less than 1 × 10¹¹ Ω-cm².

The main purpose of ESD control flooring is to help reduce possible electrostatic discharge (ESD), which accumulates as people walk, from causing damage.

Conductive elements such as carbon, graphite or metal-coated particles, distributed throughout the flooring system, give the ESD control floors electrical conductivity, and create an electrical pathway from the walking surface to ground.

Some, but not all, ESD control floors also prevent charge generation – i.e., static from accumulating as people walk. Thus, it’s critical to determine the type of footwear people will use in the space. When choosing an ESD control floor, always test for both electrical resistance and charge generation.

Resins are seamless in nature and don’t include joints or grout lines, which are susceptible to harbouring dirt, grease, bacteria and stains in general. Dust and dirt can simply be swept, mopped or hoovered away and the floor cleaned according to manufacturer’s guidelines based on the surface profile of the floor.

Resin flooring is also extremely strong and durable, meaning that it has an extended service life compared to other floor coverings. Installed properly, and with the correct maintenance, it can last for years without cracking or peeling, meaning that you won’t have to replace the floor or carry out repairs as frequently than you would if using other materials.

In scenarios where the slab is porous or the concrete has been newly laid, rising moisture can quickly impact the integrity of and negatively affect your ESD control flooring. Moisture can lead to cracking, bubbling, staining, and other physical changes to the floor, which in turn can alter the properties of your ESD floors and hinder their ability to prevent static build up.

Epoxy, polyurethane, MMA and polyurethane concrete all exhibit good resistance to a range of chemicals associated with cleaning agents or foodstuffs.

For more aggressive chemicals or food & beverages ingredients such as hydrochloric acid, sugars, oils, blood and detergents, heavy-duty polyurethane concrete provides a resistant surface underfoot.

That said, not all chemicals are created equal, so it’s important to check that your choice of flooring material will be suitable for the specific chemicals found in your processes or facility.

Industrial and manufacturing spaces are often subject to heavy loads, equipment and machinery as well as the constant coming and going of rubber-wheeled forklift truck traffic and other punishing processes.

As a result, durability in a flooring material is often critical to avoid the risk of floor failure or the surface wearing far too soon and having the headache of having to replace it all over again!

Epoxy, polyurethane and MMA resin surfaces have a longer lifespan compared to most other flooring solutions. Resin creates a hard, fast bond that is much stronger than just concrete and is highly resistant and able to withstand impact and heavy-duty industrial wear and tear.

Resin also has the advantage of offering a degree of flexibility under stress; this property gives it durability under impact and thermal shock.

An Electrostatic Protected Area, also known as an EPA, is a designated area where static is controlled under strict regulations. In an EPA all surfaces, objects, people and ESD sensitive devices are kept at the same electrical potential.

This is achieved by using only groundable with an electrical resistance typically of less than 10⁹ ohms for the covering of surfaces and for the manufacture of containers and tools.

Electrostatic discharge (ESD) is the release of static electricity when two objects come into contact. Familiar examples of ESD include the shock we receive when we walk across a carpet and touch a metal doorknob and the static electricity we feel after drying clothes in a clothes dryer. A more extreme example of ESD is a lightning bolt. While most ESD events are harmless, it can be an expensive problem in many industrial environments.

ESD first requires a build-up of an electrostatic charge. This occurs when two different materials rub together. One of the materials becomes positively charged; the other becomes negatively charged. The positively charged material now has an electrostatic charge. When that charge comes into contact with the right material, it is transferred, and we have an ESD event.

The heat from the ESD event is extremely hot, although we do not feel it when we are shocked. However, when the charge is released onto an electronic device, the intense heat from the charge can melt or vaporise the tiny parts in the card causing the device to fail. Sometimes an ESD event can damage a device, but it continues to function. This is a called a latent defect, which is hard to detect and significantly shortens the life of the device.

The chemical resistance of flooring materials largely depends on a number of specific factors, including the type of chemical, its concentration, and the temperature and degree of surface contact time.

Polyurethane Concrete

Generally speaking, polyurethane concrete systems such as vebrocrete offer a good degree of chemical resistance to a wide range or acids, alkalis, and solvents. For low to medium concentrations of organic acids such as hydrochloric, acetic, lactic and formic, polyurethane systems demonstrate excellent chemical resistance.

However, some stronger concentrations of these types of acid can cause some surface staining, usually without loss of physical strength properties even at elevated temperatures over prolonged surface contact.

Additionally, polyurethane concrete systems offer excellent chemical resistance to solvents and alkalis at low, medium and high strength concentrations at prolonged periods of contact and temperatures with minimal surface staining and loss of physical strength properties.

Methyl-methacrylate

For chemical resistance to high strength organic acids, even with prolonged exposure, methyl-methacrylate (MMA) chemistries such a vebrospeed offer superior resistance against surface staining without loss of physical strength properties. Additionally, MMA systems offer good chemical resistance to a variety of alkalis at various strength and concentrations. However MMA systems are generally not suited to solvents and should be avoided in facilities where solvents will be present.

Epoxy

Epoxy systems, such as various systems in the vebrores range, are generally suited to weak to medium strength acids including organic and inorganic acids like boric and phosphoric, but are not suited to high concentration organic and inorganic acids. Epoxy systems generally offer good chemical resistance to a variety of alkalis at various concentrations, but are more susceptible to attack from medium strength acids at elevated temperatures. Epoxy systems have limited chemical resistance to solvents dependant upon solvent type, temperature and duration of exposure.

ESD control flooring is especially important within industries where static can cause interference or damage to employees and/or equipment.

These can include electronic production and testing areas, data centres, computer chip manufacturing plants, laboratories, military bases, aerospace facilities, operating theatres and clean rooms.

Seamless epoxy resin ESD control can also be used in areas subject to fire and explosion risk, including flammable solvent and chemical stores.

The team at Vebro HQ would love to discuss your upcoming project and would be happy to talk performance characteristics and specs along with any specific functional needs you may have to ensure that you get a tailor-made flooring system that has been custom built to your individual requirements.

For the latest news, info and updates from Vebro Polymers…

The Social Hub has chosen Vebro Polymers materials to transform a number of accommodation, co-working and relaxation spaces in its Glasgow venue. The Social Hub, located in the

Read MoreAre you passionate about sales and ready to take your career to the next level? Look no further! We are seeking a dedicated and dynamic Sales Executive to

Read MoreWe are delighted to announce that Vebro Polymers is now proudly part of the Made in Britain manufacturing community. The not-for-profit organisation, dedicated to supporting British manufacturers

Read MoreVebro Polymers has manufacturing and office headquarters in Manchester, UK and Kuala Lumpur, Malaysia, as well as a number of distribution partners. Please choose your nearest Vebro HQ or distribution location to see local content.