We expect the buildings that we work, live and socialise in to be safe and free from materials that would be harmful to us and the world around us.

For almost two decades, the International Living Future Institute (ILFI) has been working towards this goal with the development of the Living Building Challenge (LBC) Red List.

What is the Red List?

You might be thinking, “I’m not sure… but it doesn’t sound good!”

Developed by the ILFI, in collaboration with the Healthy Building Network and the Pharos Project in 2006, The LBC Red List defines “worst in class” materials, chemicals, and elements known to pose serious risks to human health and the greater ecosystem.

The Red List is essentially a tool or framework that every builder and main contractor should use as we move toward the goal of truly sustainable materials.

The ILFI believe that any of the materials included on the Red List should be phased out of production entirely!

To ensure the list always remain current, the ILFI continue to evaluate and add to the Red List as each new version of the LBC Standard is released.

What is included on the Red List?

One of the fundamental directives of the LBC is that a truly restorative culture errs on the side of caution and that we simply must remove the following materials from the built environment.

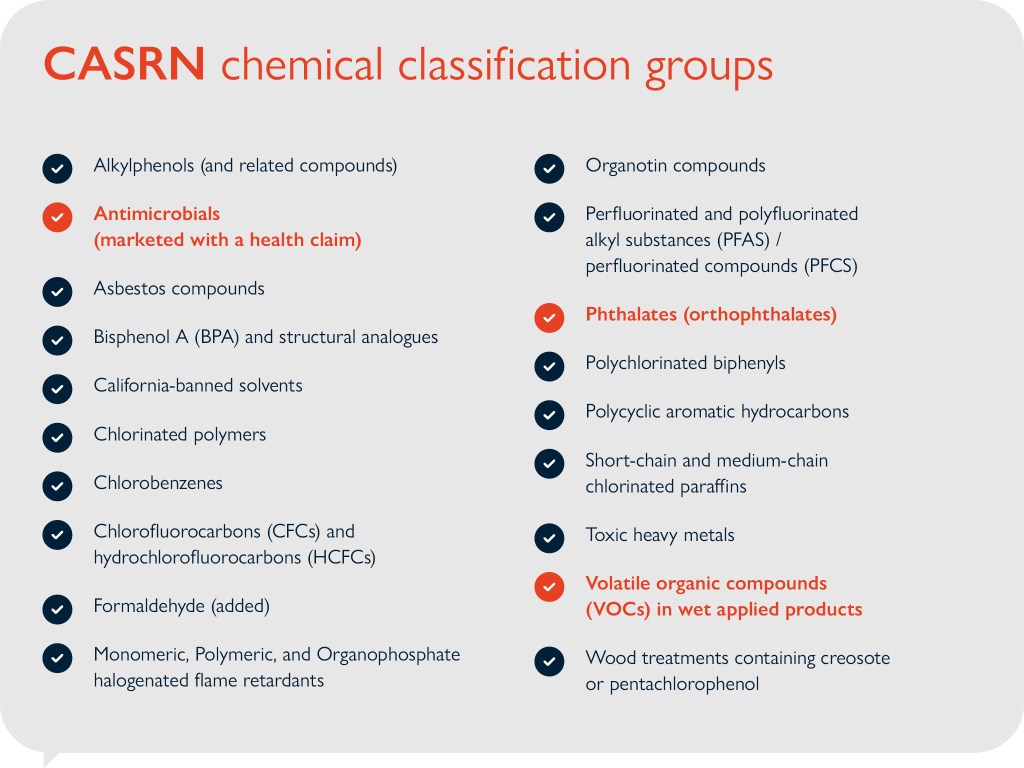

All entries on the Red List are assigned a unique Chemical Abstract Registry Number (CASRN) and are classified under various chemical groups.

vebrocrete polyurethane concrete & the Red List

The principal categories that could be related to polyurethane concrete, or cementitious urethane slurries are antimicrobials (marketed with a health claim), phthalates (orthophthalates) and volatile organic compounds (VOCs) in wet applied products.

Phthalates

Phthalates are a large group of chemicals commonly added to plastics to increase their flexibility and durability.

From energy-efficient roofing to flexible adhesives and sealants, to durable flooring and wall coverings, phthalates are used in building and construction products to make materials and surfaces last longer and easier to maintain.

Some phthalates have been linked to harmful impacts on human health. In the past few years, researchers have linked phthalates to asthma, attention-deficit hyperactivity disorder, breast cancer, obesity and type II diabetes, low IQ, neurodevelopmental issues, behavioural issues and autism spectrum disorders.

Certain phthalates are even classified as toxic for reproduction or as endocrine disruptors, which means they can interfere with the body’s sensitive hormone messaging system. Pregnant women and children are more vulnerable to negative health impacts linked to exposure to phthalates.

Some phthalates are banned in Europe. However, they are not regulated the same way outside of the EU due to their different applications.

vebrocrete polyurethane concrete materials from Vebro Polymers are all based on non-toxic, phthalate-free formulations.

Volatile organic compounds (VOCs)

Volatile organic compounds are compounds that have a high vapour pressure and low water solubility.

Many VOCs are human-made chemicals that are used and produced in the manufacture of paints and lacquers, paint strippers, cleaning supplies, pesticides and building materials.

Volatile organic compounds (VOCs) are emitted as gases from certain solids or liquids.

VOCs are especially problematic when used indoors or in areas of limited ventilation. Concentrations of VOCs are consistently higher indoors (up to ten times higher) than outdoors. VOCs include a variety of chemicals, some of which may have short- and long-term adverse health effects.

The most common VOCs as it relates to resinous flooring products are found in solvents. Solvents include such chemicals as: xylene, acetone, toluene, ethyl acetate, MEK, and others. These solvents are designed to evaporate at room temperature at different rates depending on their intent. They are used to reduce the viscosity of the material (make it thinner) and act as a carrying agent for resins as they penetrate a substrate, improving adhesion and extending working times.

vebrocrete polyurethane concrete materials from Vebro Polymers are all based on extremely low VOC formulations, complying well within the parameters of EU-Directive 2004/42 Category J Type SB (< 500 g/l).

vebrocrete PU HF: < 12 g/l

vebrocrete PU Coating: < 15 g/l

vebrocrete PU Cove: < 6 g/l

Antimicrobials

Antimicrobials are a class of chemicals designed to kill or inhibit the growth of microbes.

Antimicrobials are frequently used in building materials, including countertops, paints and flooring where they act as a preservative for the materials themselves.

However, the labelling, advertising, and marketing of products associated with antimicrobials are often confusing and may strongly imply a level of protection from bacteria and viruses that have been explicitly refuted by the United States Center for Disease Control. Particularly where the health benefits of their use have not been established or substantiated – something which has been acknowledged by manufacturers of antimicrobials as well.

A message from Thomson Research Associates, Inc. (TRA)’s regarding their product “Ultrafresh” and its built-in antimicrobial technologies “…Our antimicrobial technologies are effective against a broad range of product-damaging microbes, but are not currently proven to have any antiviral properties when built into products. The active technology itself may be effective against viruses in pure state, but not when incorporated into a product…”

Interest in building products with applied antimicrobial treatments has increased significantly during the recent global COVID-19 pandemic. Like phthalates, some antimicrobials have been classified as endocrine disruptors and have been shown to impair learning and weaken muscle function.

ILFI continues to monitor the situation and commits to presenting current information about reported or potential human and environmental health impacts of antimicrobial substances as commonly used within the building industry and supporting its community of users in best utilising this information in their own practice.

Antimicrobial additives marketing health benefits to end user have been deliberately and purposefully excluded form vebrocrete polyurethane concrete materials from Vebro Polymers.

The Red List: Frequently asked questions

Red List Materials

The National Building Specification (NBS) now requests that all manufacturers listing their products on NBS Source to declare any Red List items, so specifiers can be confident that they have all the information they need to make informed decisions when specifying products and systems.

As the chemicals and compounds in the Red List are of varying levels of toxicity, there have been material evaluation programs created to ensure building materials containing any of the items on this list are properly identified.

This includes declaration, which requires a manufacturer to disclose all their product’s constituent chemicals and materials, including the amount present (to the designated 100 parts per million of PPM). The manufacturer is required to report the extent that their product is compliant with the Red List. Compliance to the Red List typically comes in three levels:

- Free: The product is completely devoid of any of the items that appear in the Red List

- Compliant: The product may contain some chemicals that has been designated as temporary Red List exceptions for one reason or another

- Declared: Products in this level are not compliant at all with the Red List or any specified temporary exceptions

The Red List is updated yearly with chemicals that have well-established research pointing to their toxicity. It considers the evolution of voluntary restricted substances lists, global regulations and innovation of the building products manufacturing industry.

The Watch List is an accessory to the Red List and contains materials under scrutiny.

This list gives the industry a warning that ILFI aims to add the chemical to the official Red List in one year.

The Watch List fills an important gap in identifying and prioritising chemicals for Red List inclusion and serves as a buffer for projects already under construction.

The future of manufacturing in the construction chemicals industry

Right now, there are many limitations that prohibit builders from truly complying with the Red List, however, its aim is to push the industry in the right direction, fostering innovation and communication.

The Red List is providing all stakeholders involved in the construction process with a shifted mindset that is going to really impact the way we think about products.

Within the LBC framework, the Red List continuously pushes product manufacturers to start rethinking how they build and formulate their products.

And while this list provides the industry with a quantifiable end goal, the more exciting aspect of the list is that it is not static and evolves as we do.