the challenge

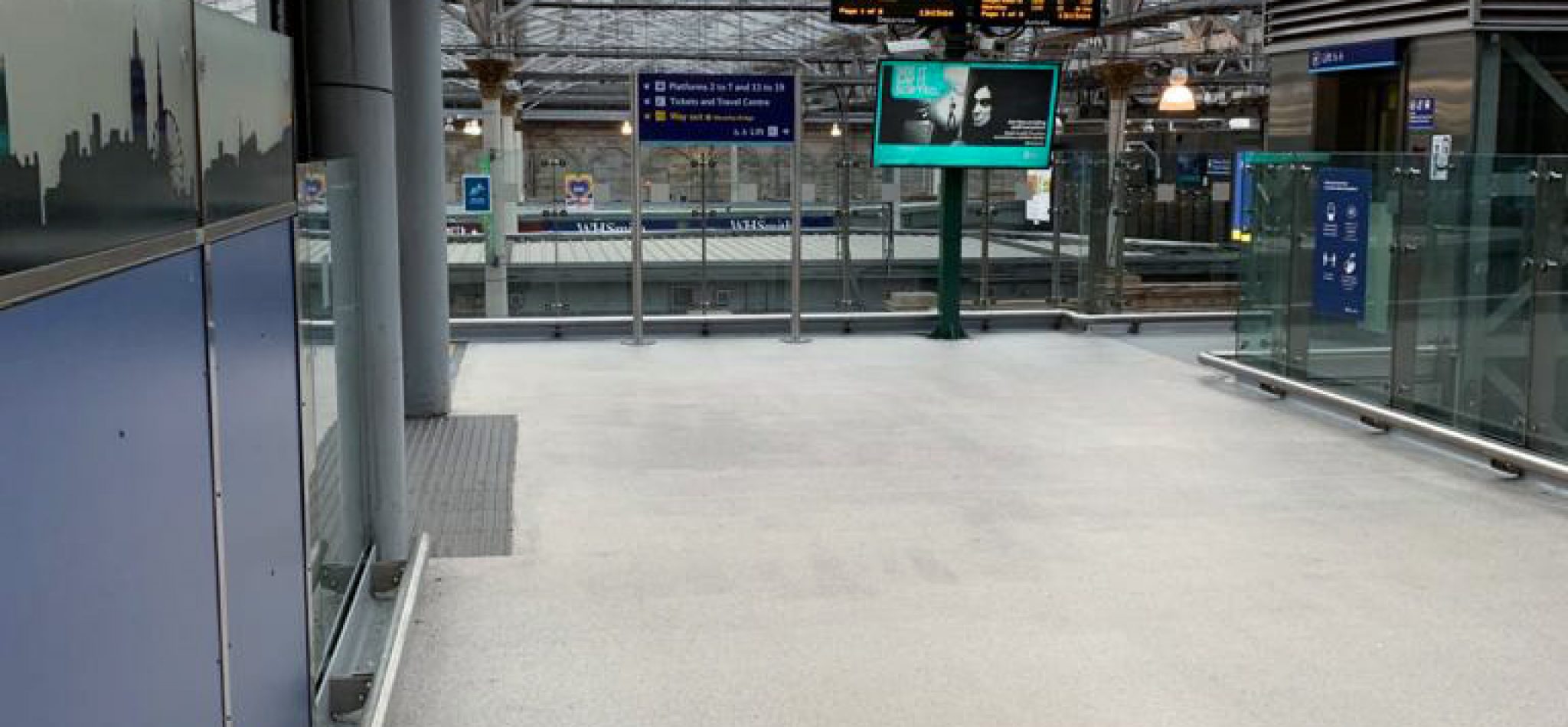

A fast-cure flooring system that would minimise disruption to daily operations for upgrade works to a floor mezzanine and stairwell at the iconic Edinburgh Waverley railway station.

meet the client

Edinburgh Waverley railway station is an architectural icon located in the centre of Edinburgh and the second busiest station in Scotland, after Glasgow Central.

The station has many Victorian architectural elements – including the booking hall – but has also been recently renovated with a new roof that provides great natural light to the terminal below.

the project

Network Rail has invested £1.8 million towards refurbishing the station’s toilets, improving the floor surface on the mezzanine walkways and stairwell in the station as well as reopening a public access corridor through the main building. The toilet facilities will be replaced with energy efficient systems and fittings.

Work has also begun on a new public corridor which will connect the east concourse with the ticket hall – restoring a walking route which was part of the original station design.

Vebro’s solution

Improvements to the flooring on the concourse mezzanine level have already been completed by commercial and industrial flooring specialists, IFP Scotland, using a fast-cure, slip-resistant and decorative MMA resin system designed to minimise any disruption to the station’s operations throughout the refurbishment.

vebrospeed Quartz SR is a decorative, fast curing MMA flooring system used in areas subject to frequent pedestrian traffic, as well as surfaces that can be become slippery from inclement weather and dirt tracked in on wet shoes and boots.

The system is positively textured to promote safety underfoot, minimising the risk of slip, skid and trip accidents.

The material was installed in two decorative quartz blends, Pebble Beach and Rainstorm.

IFP installed the material over the existing tiled finish using a specialist primer to ensure adhesion to the substrate before installing the MMA quartz system.

vebrospeed Flake, a fast-cure resin system that sees coloured flakes broadcast into the MMA resin binder before being sealed for a smooth finish was chosen for the stairwell refurbishment in our White Russian flake blend.

MMA resins are an excellent choice for floor refurbishment works owing to their rapid installation and fast-cure properties – full foot and vehicular traffic is accepted by the system within just 60 minutes of installation.

meet the installer

IFP (short for Industrial Floor Preparation) Scotland, based in Livingston, West Lothian, has over 50 years of experience in the art of surface preparation including diamond grinding and shotblasting substrates prior to the installation of floor coverings.

The team has also carried out a number of high-profile seamless resin floor installation projects including the Printworks, Glasgow and Queensferry Crossing.

key project details

client

location

year

project size

Vebro systems

Want to know more?

To learn more about how Vebro can assist you, or to make an enquiry, simply…

keep up to date Latest News

Mark Verinder on Made in Britain UnPacked: shining a light on resin flooring leadership

Vebro Polymers' CEO, Mark Verinder, has featured on UnPacked, the online video series produced by Made in Britain that spotlights standout leaders shaping the future of UK manufacturing.

Read MoreVebro Polymers Ignites Southern Expansion with the Arrival of Michael Cross

In the ever-evolving tapestry of the UK construction landscape, few regions command attention like the South of England. With London and its surrounding counties driving a remarkable share

Read MoreHigh-Voltage Safety Flooring That Means Business

Vebro Polymers is turning heads with the launch of vebro EP DE, a next-generation, solvent-free, insulative epoxy flooring system designed to combine high-voltage protection with durability, seamless installation,

Read MoreFancy a cookie?

This website uses cookies to improve your experience. We'll assume you're ok with this, but you can opt-out if you wish. Cookie settingsAcceptCookie Policy Overview

Out of these cookies, the cookies that are categorised as necessary are stored on your browser as they are essential for the working of basic functionalities of the website.

We also use third-party cookies that help us analyse and understand how you use this website.

These cookies will be stored in your browser only with your consent. You also have the option to opt-out of these cookies. But opting out of some of these cookies may have an effect on your browsing experience.

Read the full Cookie Policy here.

where in the world?

Not seeing local content?

Vebro Polymers has manufacturing and office headquarters in Manchester, UK and Kuala Lumpur, Malaysia, as well as a number of distribution partners. Please choose your nearest Vebro HQ or distribution location to see local content.